Construction site photos

Product introduction:

Besides conquering the challenge of cathode protection of old pipes successively,BS-JB39-52 flexible conductive polymer anode can also solve some difficulties in the traditional cathode protection technology universally, for instance, the interference in external structures, the implementation of cathode protection in the environment medium with high resistivity and the current distribution of cathode protection at the bottom of the storage tank. It features even current distribution, low energy consumption, long service life of anode, etc.

|

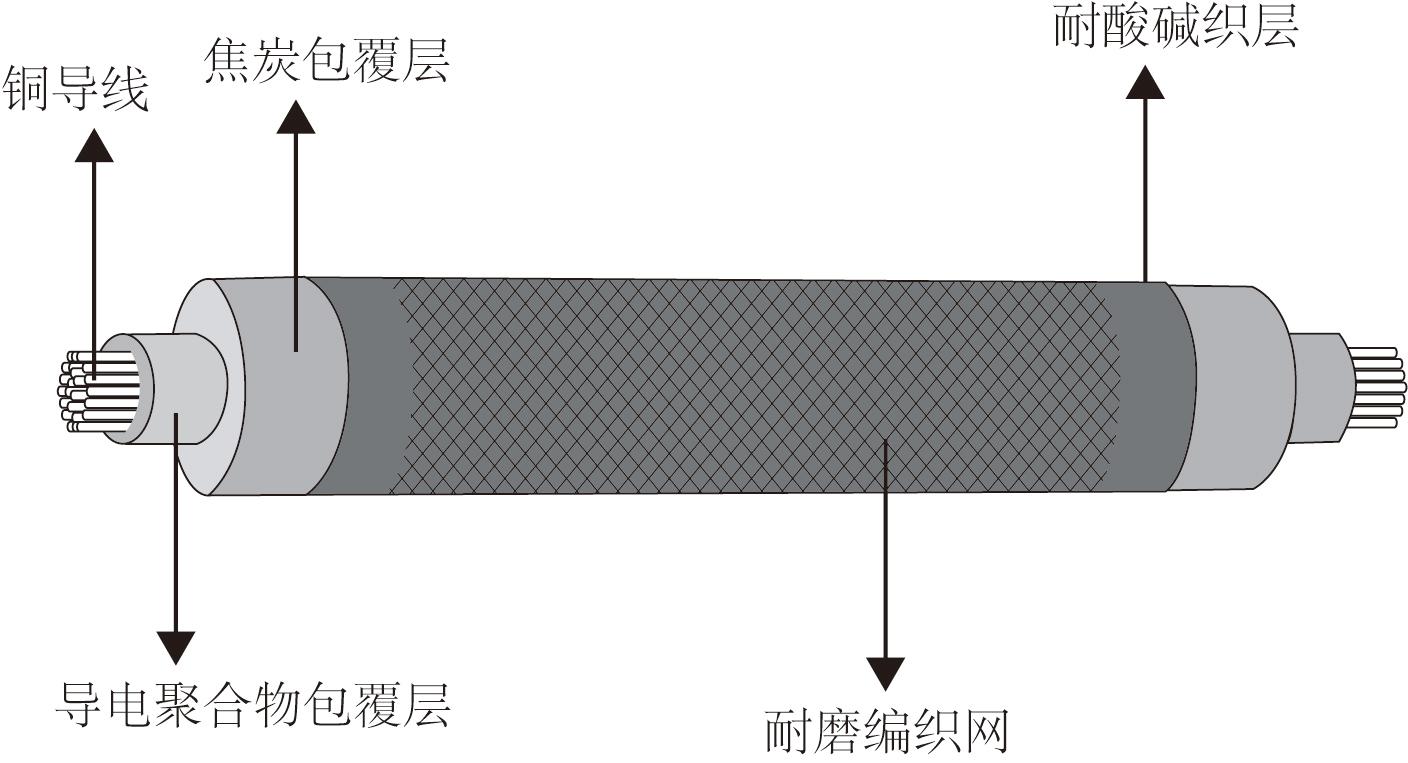

Copper conductor |

Coke cladding layer |

|

Acid-base resistant braiding layer |

Conductive polymer cladding layer |

|

Abrasion resistant braiding net |

|

|

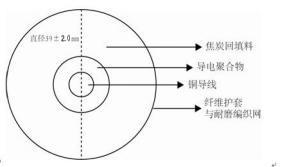

Diameter 39㊣2.0mm |

Coke backfill material |

|

Conductive polymer |

Copper conductor |

|

Fiber sheath and abrasion resistant braiding net |

|

Characteristics:

♂ Continuous conductive polymer anode

♂ Continuous internal copper-core cable

♂Coke filled in fabric cladding layer

♂ Breathable fabric cladding

Advantages:

♂ Evenly distributed output current; even the anti-corrosive coating of the pipe is damaged seriously, the even distribution of current can also be guaranteed to realize cathode protection;

♂Evenly distributed electric potential avoids excessive and insufficient protection;

♂Good pertinence leads to small interference in other metal structures

♂ Small interference in the stray current can solve shield and interference issues in complex pipe network areas;

♂ Share the trench with pipes solves the issue of anode laying in zones with rock and high resistivity;

♂ Easy installation; packaged product can be installed directly and requires no additional components and materials

♂ Simple and convenient construction; construct simultaneously with pipes and share trench with them to facilitate installation. Meanwhile, the current loss can is decreased significantly and the utilization efficiency of protection current is improved.

Installation mode:

♂ Cable traction type laying

♂ Trench excavation for laying

♂ Laying on the sand layer at tank bottom or between tanks

Application scopes of BS-JB39-52 flexible conductive polymer anode

♂ Cathode protection for pipes with degraded and seriously damaged coating

♂Cathode protection for pipes in areas with stonework and high soil resistivity

♂ Regional cathode protection for underground metal facilities regional cathode protection for oil and gas transportation station yard, petrochemical plant, power plant

♂ Cathode protection for floors and external walls of storage tanks

|

Item |

Index |

|

Diameter of flexible anode |

39㊣2 mm |

|

Average thickness of conductive polymer |

≡ 4mm |

|

Volume resistivity of conductive polymer |

1.1次﹞和-1.9次﹞和 |

|

Maximum output current |

52mA/m |

|

Design service life of anode |

≡40 years (at rated work current) |

|

Carbon content of filled coke powder |

≡98% |

|

Resistivity of coke powder |

≒0.55次﹞cm |

|

Fabric cladding layer of anode |

Resistant to acid, base and chlorine; permeable |

|

External braiding net |

Resistant to abrasion and change of environment temperature |

|

Anode weight |

≡1.3Kg/m |

|

Length of each reel of anode |

500, 700m (or customized) |